Home

Back

My watercooled Lian Li PC-70

project

Page 2

(more or less) Chronological pictures of the

project:

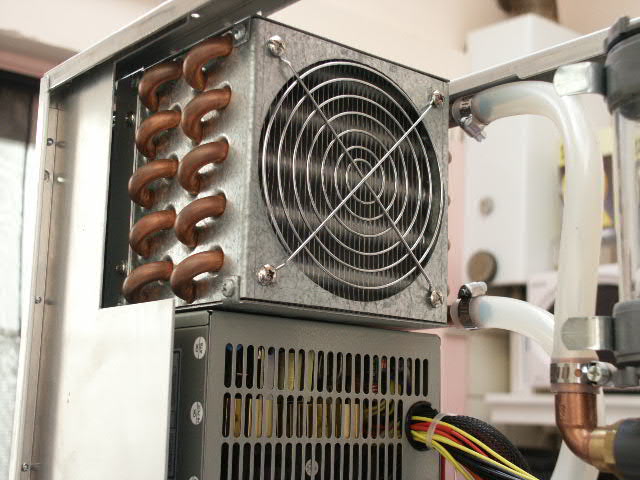

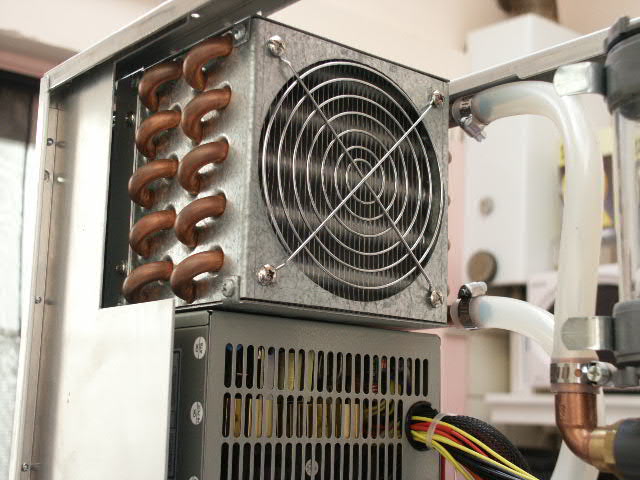

A general view of my Lian Li PC-70. All hoses are 1/2" silicon tubing and

are fixed with hose clamps.

All PVC parts have an ID of 20mm (a little more than 3/4"), the copper

tube is 15mm OD (a little more than 1/2").

The radiator is the new AquaCoil II with two 3/8" parallel waterways and

1/2" connections.

AquaCoil II radiator & Enermax 550W. I drilled the rivets of the L-shaped

alu plate near and beneath the PSU. Than I removed a part to clear the radiator

(on the left) and for the 92mm fan of the Enermax (at the bottom).

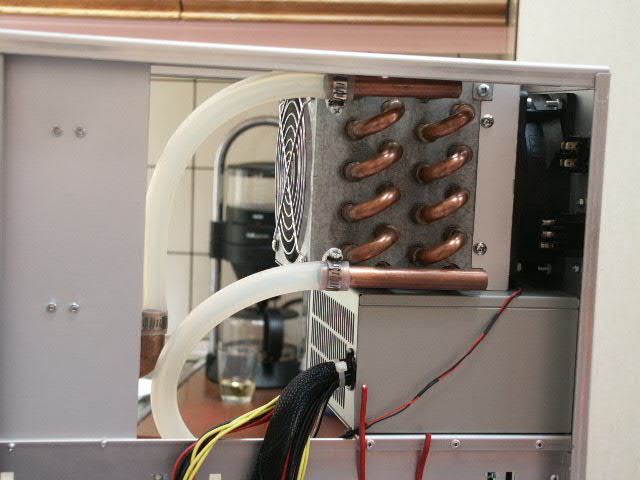

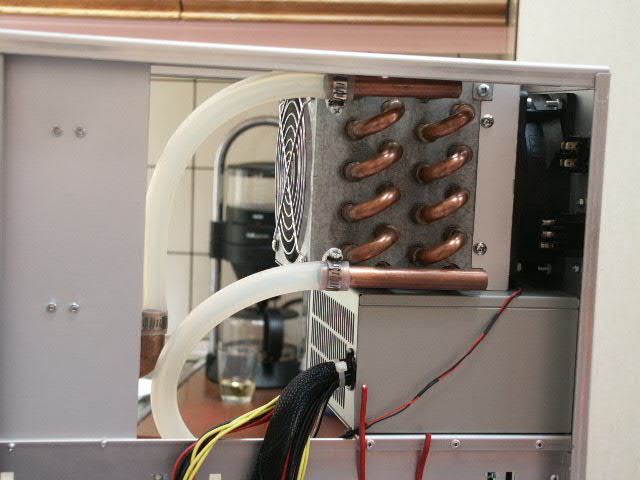

View from the other side + Panaflo L1A fan.

Between the Panaflo and the AquaCoil radiator I mounted an aluminium (1mm

anodized) shroud of about 2.5cm (1") so that I could mount the Panaflo on

the other side of the radiator (sucking air instead of blowing), and so that

the Panaflo is 1.5" away from the cooling fins.

The hole for the 92mm fan of the Enermax + modded Swiftech. I inversed the two

rear 80mm fans so that they blow air into the case together with the two front

fans. Input is now about 124CFM (4x 31CFM) and Output (Enermax + 120mm Panaflo

L1A (69CFM)) is about 100CFM, so that I have a little positive pressure in the

case.

This is not a reservoir but an "airtrap" at almost the highest point

of the system to "trap" or bleed remaining air bubbles in the water,

and also to have a visual indication of the water level. Since the upper cover

is removable I can add water to the circuit.

The PVC-part is made of 50mm OD PVC (2") and two hermetic endcaps with a

screwed cover of 50mm + about 15cm (6") plexi tube of also 50mm diameter.

On the T-part is mounted two brass adaptors (1/2" to 15mm) to connect to

the 15mm copper tube.

The 90° copper turns are hardsoldered to the brass adaptors.

Sicce Idra 1300 liter/hour pump (320gallon/hour) + bleeding & filling

system with Eheim taps (petshop).

The big tap has a 3/8" thread and is screwed to the PVC via 1/2" to

3/8" brass adaptors with Teflon.

The two little taps (1/4" thread) are screwed with Teflon via 1/4" to

1/2" brass adaptors. Everything is screwed to the chassis via the two 27mm

clamps. All PVC parts have an ID of 20mm.

Between the PVC-part and the pump is a little piece (4cm) of 20mm silicone tube

to prevent vibrations from the pump to pass to the chassis. The pump itself is

mounted on rubber suckers.

The two little taps are used to fill and bleed the system (via 3/8"

silicone tube to a "jerrycan" with cooling fluid).

All PVC is glued with "hardPVC" glue.

The rear side of the PC-70.

The front side.

The new "PSU mounting plate" with Panaflo L1A. I made it using the

original mounting plate as a model + the additional hole for the Panaflo. I had

to rotate the hole for the PSU because originally the PSU is mounted with the

92mm fan upwards. Beneath the Panaflo is the AC connection and switch for the

waterpump.

"Spoilers" near the fans to prevent the two 80mm fans to suck in hot

air from the PSU and the Panaflo (I smoked a lot of sigarets just to see where

the airflow of the fans was going).

Previous

1 2

3 4

5 6

7

8 9

10 11

12

13 14

15 16

17

18 19

Next